In this new blog entry we will review some matters to take into account during the packaging of the seminal doses.

There are multiple factors that can have an impact on the quality of sperm doses produced by a boar stud. The last stage that can influence on quality is packaging, which many times, being the last one, can go unnoticed, or not be given the right importance.

In this process, the quality of seminal doses could be altered by a lack of hygiene or an inadequate filling process.

To avoid this, these are some pieces of advice to follow:

Hygienic measures for the proper preservation of hygiene during filling:

In the case of using automatic or semi-automatic packaging systems, rubber pipes or filling tubes can be a source of contamination when proper hygiene measures are not taken. To avoid this, we must take the following into account:

- In the case of silicone rubber and sterilizable material (filling needle and weight) that withstand sterilization, the cleaning should be carried out as follows:

- Wash with a non-foaming pH-neutral detergent, rinse with distilled water and sterilize at 120-140 ° C for 90-120 minutes

- In the case of non-sterilizable rubber hoses:

- Wash with non-foaming pH-neutral detergent, rinse with distilled water, pour 70° ethanol and let it evaporate till the following use.

- Homogenization or washing of the hose for packaging: At the beginning of the day and after every boar, it is advisable to let some extender run through the pipes. This practice is carried out with 2 objectives:

- when the day begins, to eliminate any residues of the cleaning processes that have remained in the hoses.

- After every boar, to avoid bacterial cross-contamination and avoid mixing different breeds or genetic lines.

It is more advantageous to perform these washes with extender, as it helps preserve osmolality, while distilled water could leave remains and alter the osmotic pressure of the first seminal doses.

- In the case of suspicion that any boar may have contamination problems, pack their doses at the end of the work day (these boars should always be the last ones to be collected and processed in the laboratory)

- To avoid bacterial contamination, we recommend to use to use as much disposable material as possible, so Magapor launched a fungible product for this process called Higytube.

Accuracy during the filling process, in order to avoid variation in the number of sperm cells of seminal doses:

Packaging is the last stage in which we can negatively influence the accuracy of the amount of sperm cells that we want to have in the seminal doses produced. Therefore, there are some aspects that we must bear in mind. We can influence due to mistakes in the dosage of the volume or to an incorrect or absence of homogenization of the already diluted ejaculate, since the total number of sperm in a seminal dose will be set by the volume of the dose, and by the concentration of sperm cells per milliliter.

Therefore, the following points must be kept in mind:

- There should not be greater variation than 2.5-4% of the target volume between seminal doses. These differences are only possible using automatic packaging equipment. It is very unlikely having smaller variations performing manual packaging, due to the time that must be invested.

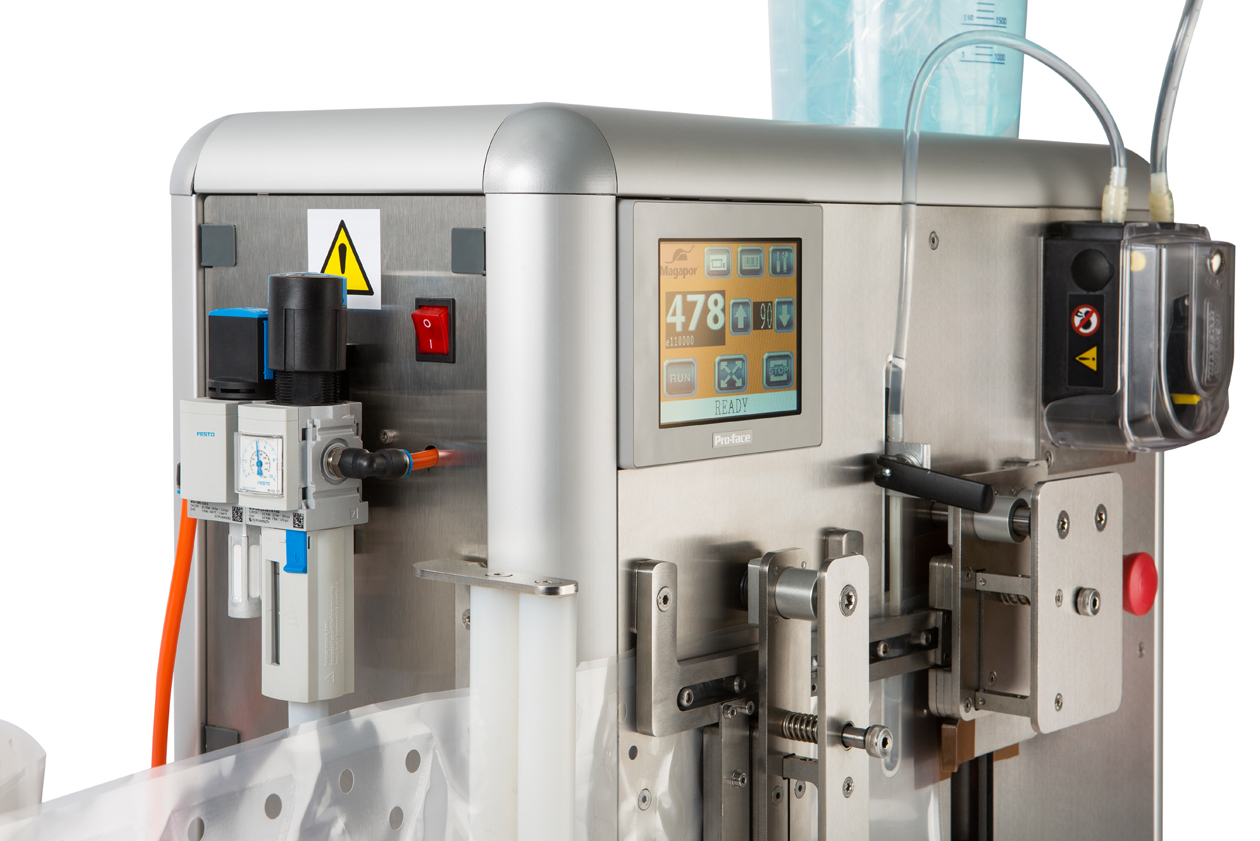

- Calibration of automatic packaging equipment: At the beginning of the working day and whenever the packaging rubber is changed, the calibration of the volume poured by the machine pump must be performed.

- Proper condition of rubber pipes for packaging: Although we perform the calibration of the machine, if we use pipes/tubes whose silicone or plastic is heavily worn, we will have variations in the dosed volumes.

- Homogenization of the ejaculate prior to packaging: If it has been a long time since we have mixed the ejaculate and the extender, and even more so when the mixture is at a temperature close to that of the conservation (lower sperm activity), the sperm cells will fall to the bottom of the container. Therefore, before packaging we must homogenize the mixture. For this we can use the rubber itself and packaging weight that will aspirate the content of the container.

All these recommendations and aspects to be taken into account will help preserve the quality of the seminal doses during the packaging process. We hope you find them useful and practical.

In next blog entries we will publish:

- an interesting clinical case of bacterial contamination in seminal doses, due to the rubber hoses/tubes for packaging

- advantages of our Extenderbox

Visit our blog soon!!!!